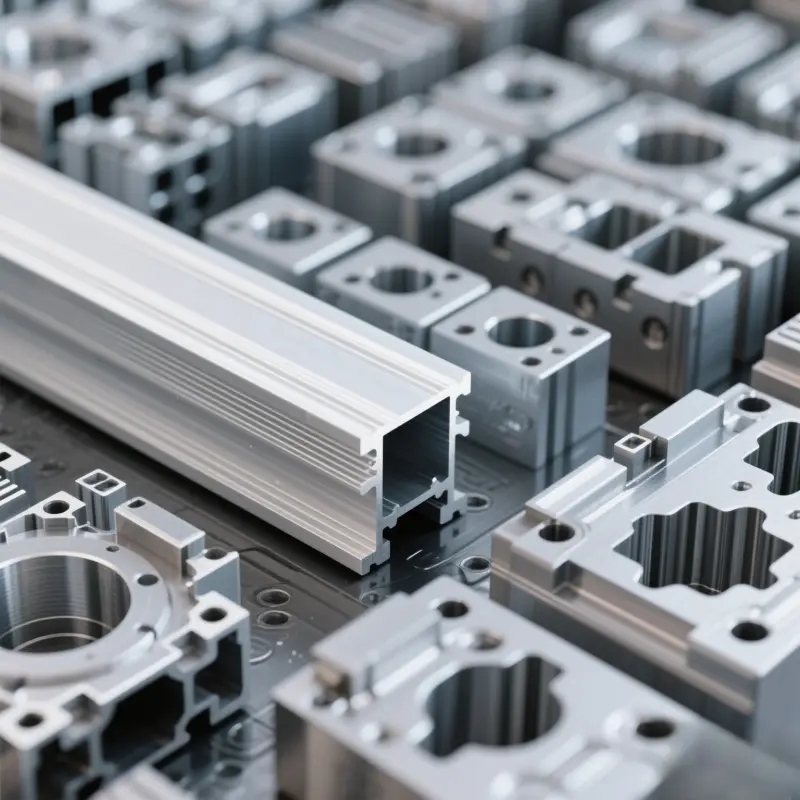

Profilés en aluminium personnalisés selon vos dessins et vos exigences

Personnalisation et savoir-faire Sunmay

Gamme d'application des produits

Découvrez les principales différences entre les profilés en aluminium architecturaux et les profilés en aluminium industriels et trouvez la solution idéale pour vos besoins de construction ou de fabrication.

| Profilé architectural en aluminium | Profilé en aluminium industriel | ||

| Fenêtres et portes | murs-rideaux | Dissipateurs de chaleur | Cadres d'énergie solaire |

| Systèmes de coffrage | Mains courantes | Structures de dispositifs médicaux | Composants du transport ferroviaire |

| Persiennes | Vérandas | Pièces de construction navale | Assemblages aérospatiaux |

| Cadres de meubles | Systèmes de partitionnement | Enceintes de machines | Équipement d'automatisation |

| Grilles de plafond | Façades décoratives | Structures de salles blanches | Composants du système de convoyeur |

Pourquoi nous choisir?

Fabriqué avec précision profilés en aluminium pour les applications de construction et industrielles, avec des solutions personnalisées, des matériaux de haute qualité et une livraison mondiale fiable.

Revêtement en poudre de profilés en aluminium sur mesure

Nos profilés en aluminium sur mesure bénéficient d'un traitement imitation bois de haute qualité, alliant l'attrait intemporel du bois naturel à la durabilité et à la résistance de l'aluminium. Grâce à une technologie avancée d'impression par transfert par sublimation, nous garantissons à chaque profilé un aspect bois réaliste, avec une meilleure tenue des couleurs, une résistance supérieure aux UV et une protection contre les intempéries. Ce procédé consiste à appliquer un transfert thermique qui colle le motif du bois directement sur la surface de l'aluminium, créant ainsi une finition uniforme et durable. Le résultat est une finition résistante aux rayures, à la corrosion et aux intempéries, idéale pour les applications intérieures comme extérieures.

Nos profilés en aluminium effet bois sont disponibles dans une large gamme de motifs de bois naturels tels que le chêne, le noyer, le teck et le cerisier, offrant une alternative durable aux surfaces en bois traditionnelles. Ces profilés sont parfaits pour de nombreuses applications, notamment les portes, les fenêtres, les murs-rideaux, les vérandas et les encadrements de meubles. Ils offrent une esthétique haut de gamme tout en conservant la légèreté, la durabilité et l'absence d'entretien de l'aluminium.

Revêtement en poudre de profilés en aluminium sur mesure

?? Pour le marché nord-américain – Utilisation architecturale (fenêtres et murs-rideaux)

Nos profilés en aluminium sur mesure pour le secteur de la construction nord-américain bénéficient de traitements avancés de sablage et de thermolaquage, garantissant une adhérence supérieure et une résistance durable aux climats rigoureux. Conçus conformément aux normes AAMA 2603/2604, ces profilés offrent une protection UV élevée, une résistance à la corrosion et une texture élégante, idéale pour les fenêtres, les murs-rideaux et les vérandas.

Conformes à la norme EN 12206-1, nos profilés en aluminium utilisés dans les châssis d'automatisation et les structures industrielles bénéficient d'un sablage de précision pour une meilleure adhérence de surface, suivi d'un revêtement en poudre à faible teneur en COV pour une conformité environnementale et une durabilité exceptionnelle. Ce procédé améliore la résistance à l'usure tout en garantissant une esthétique élégante et des performances optimales sous forte charge.

Conçus pour résister aux chaleurs extrêmes et aux UV, nos profilés en aluminium sablés et thermolaqués sont optimisés pour les cadres de panneaux solaires, les systèmes d'ombrage et les façades écoénergétiques. Leur finition résiste à l'oxydation et à la décoloration, même dans les climats désertiques, garantissant une longue durée de vie avec un entretien minimal.

Notre procédé de traitement de surface comprend un sablage profond pour une texture d'ancrage optimale et un revêtement en poudre polyester haute densité, créant une couche robuste et résistante à la corrosion. Offrant d'excellentes performances en extérieur, ces finitions sont idéales pour les systèmes de rayonnages solaires, les assemblages à rupture de pont thermique et les composants d'infrastructures énergétiques.

R : Oui. Sunmay est spécialisé dans l'extrusion d'aluminium sur mesure, selon vos plans CAO et vos exigences spécifiques. Nous proposons une personnalisation complète des profilés en aluminium architecturaux et industriels.

A : Nous fabriquons une large gamme de profilés en aluminium architecturaux (fenêtres, portes, murs-rideaux, façades) et de profilés en aluminium industriels (châssis de machines, systèmes d'automatisation, composants d'énergie solaire).

R : Nous travaillons avec des alliages hautes performances comme le 6061, le 6063, le 6005, le 6082 et le 7075, en fonction des exigences de résistance, de résistance à la corrosion et de finition de surface.

R : Sunmay propose l'anodisation, le revêtement en poudre, l'électrophorèse, les finitions en grain de bois et les finitions personnalisées adaptées aux applications intérieures et extérieures.

R : Oui. Nous proposons des emballages d'exportation sécurisés, prenons en charge l'étiquetage personnalisé et fournissons des services logistiques pour la livraison dans le monde entier, garantissant ainsi que votre commande arrive à temps et en toute sécurité.

R : Notre quantité minimale de commande standard est de 500 à 1 000 kg par modèle, selon la complexité du profil. Nous proposons également des solutions pour les commandes d'essai ou les nouveaux projets de développement.

R : L'outillage prend 7 à 10 jours, et la production en série prend généralement 15 à 25 jours après confirmation de l'échantillon. Nous garantissons des délais de livraison rapides et fiables.

R : Oui. Tous les produits sont fabriqués selon la norme de gestion de la qualité ISO 9001, avec des options pour répondre aux normes RoHS, REACH et GB/T ou EN sur demande.

R : Absolument. Nos ingénieurs offrent des consultations de conception gratuites, incluant l'examen des fichiers CAO, l'analyse de faisabilité de l'extrusion et l'accompagnement à l'optimisation des coûts.

R : Oui. Nous proposons des services OEM, une personnalisation de marque et des emballages sur mesure pour les clients internationaux, les grossistes et les partenaires de projets.

Whatsapp : +8617366266559

E-mail : sales@sunmayalu.com

Tél : +86 -17366266559

Hi! Click one of our members below to chat on